PRODUCTS

Integrated Planning for Equipment Monitoring Systems

What can we do?

HU Real-life Cases

Lead screw detector

Client Requirements:

In case of abnormalities in the conveyor mechanism (such as belt breakage, loosening, or bearing damage), the system should promptly detect and transmit interlock signals to the machine. Minimize and prevent abnormalities in wafer position.

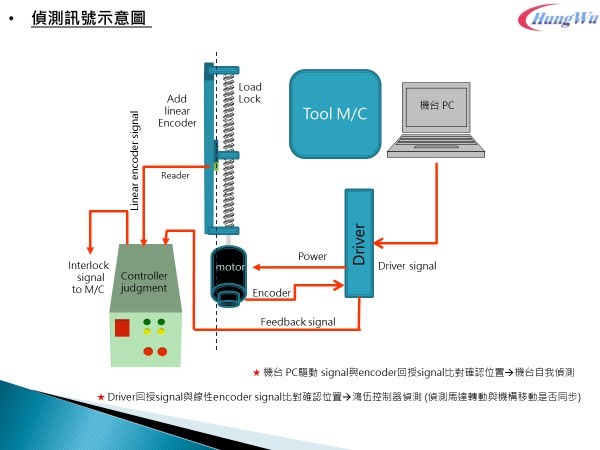

Utilized Expertise:

Detection of the consistency between the motor rotation driving the mechanism and the distance of screw and motor rotation at the machine end. Allowance for setting the error value between motor rotation distance and mechanism displacement. Continuous monitoring for excessively large error values exceeding the set time.

Robot 震動偵測

Client Requirements:

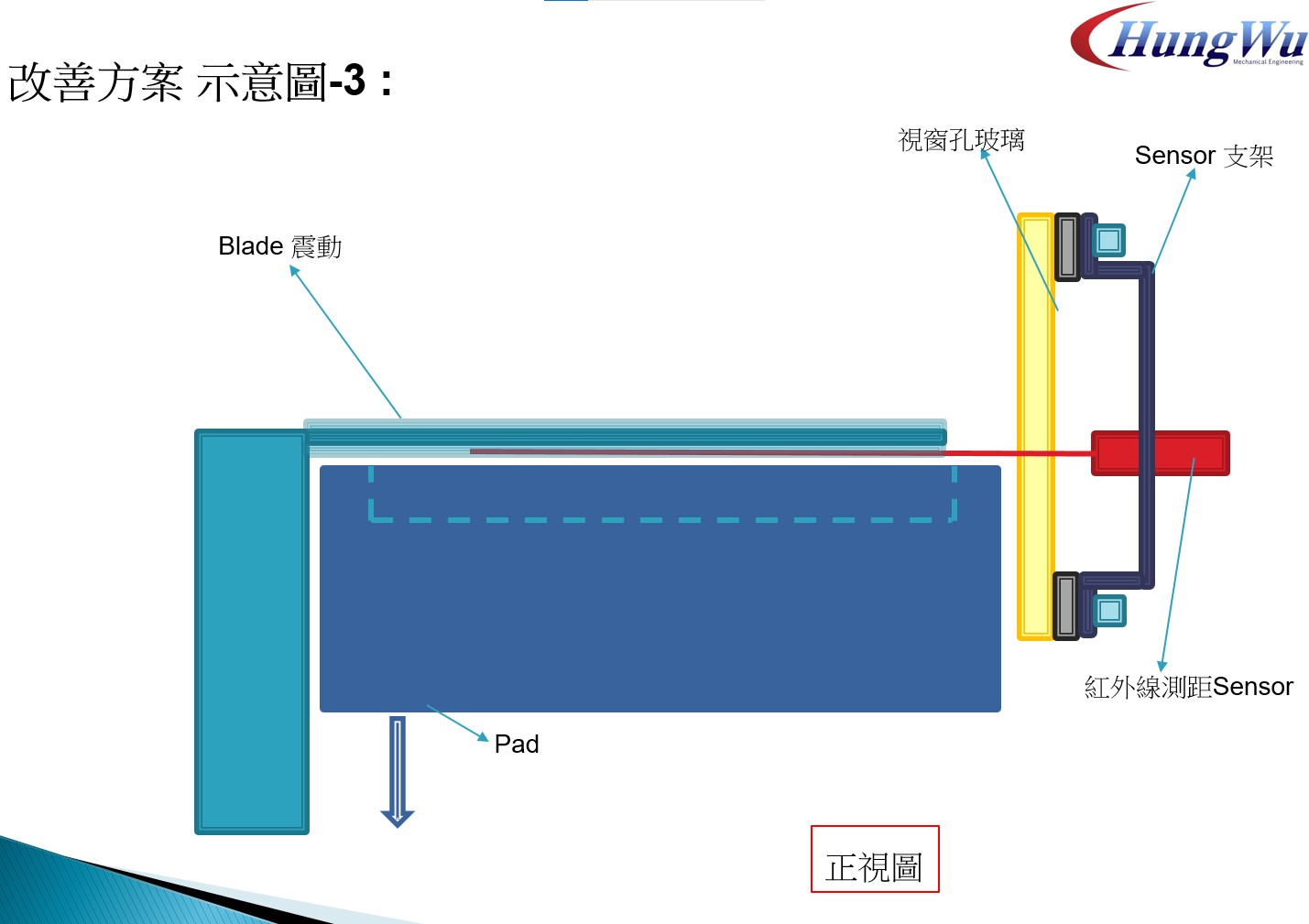

The Effector Robot Blade, when returning to its original position, occasionally fails to reach the designated location. When the Cooling Pad ascends, it pushes the Effector Robot upward, causing vibrations when the Cooling Pad descends. The client wishes to install a vibration sensor above the Robot to detect its vibrations.

Utilized Expertise:

Installation of an infrared distance sensor in the window and capturing motor signals controlling the Cooling Pad. When the vacuum gauge value exceeds the set threshold, an on/off signal is output, triggering vibration detection based on the detected vibration CMD signal.

Multi

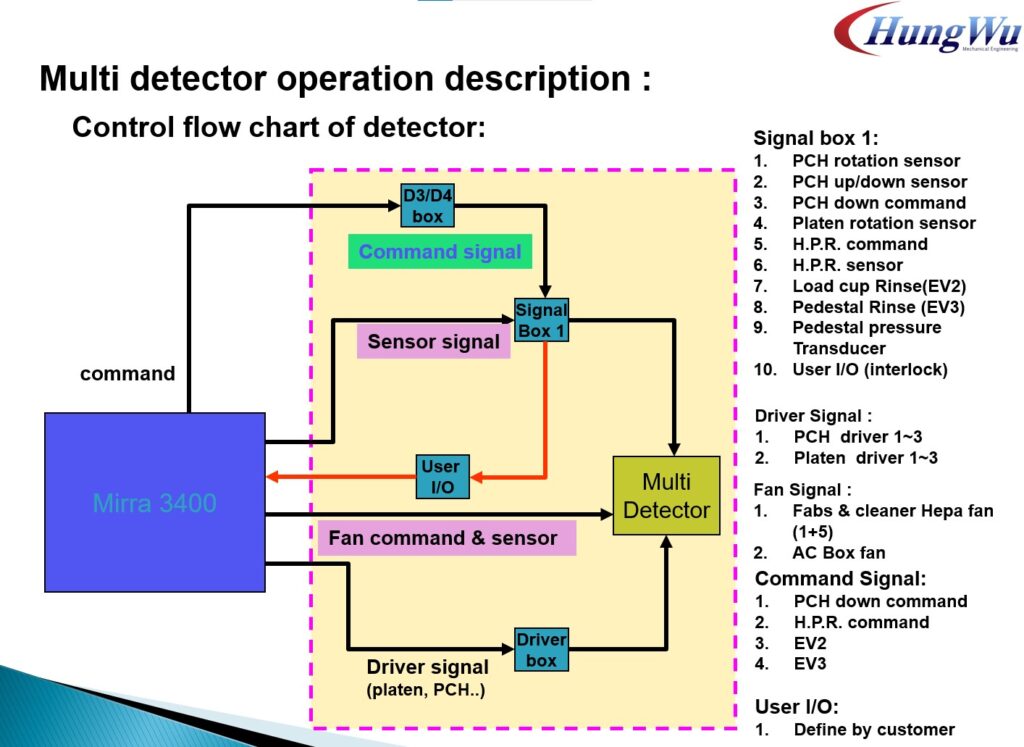

Client Requirements:

Detection of various parameters to ensure compliance with customer specifications. Implementation of safety measures to protect customer products from any adverse effects.

Utilized Expertise:

Utilization of specialized sensors along with controllers for detecting the required parameters specified by the customer. Incorporation of multifunctional detection and integration capabilities to tailor the system for the diverse detection needs of the customer.